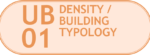

UB06 DISTRICT HEATING

Concentrate thermal generation infrastructure with renewable energy to service several buildings

Aim

To efficiently implement heat generation infrastructures that serve and supply inhabitants and their activities. The concentration of energy systems lead to an optimum management of both production and makes the necessary infrastructures more efficient.

Why?

One of the main goals in the search of sustainable cities is the raising of the efficiency in heat generating systems with renewable energies that serve and supply the inhabitants and the activities in a given area. Technological advances have made it possible to overcome many drawbacks of centralised systems.

Advantages:

• Better performance

• Savings in space taken by equipment

• Access to an energy source with an economically competitive cost

• Reduced investment in equipment

• Reduced management

• More efficient equipment that reduces environmental impact

• More time and cost effective centralised management and maintenance

• Monitoring of environmental impact

• Makes the use of renewable energies and waste heat possible

• Makes it possible to use non-polluting refrigerants

• Diversified energy supply

Como?

District heating is produced in a power plant and distributed through an urban network to serve several buildings. Hot water from a heat production plant is distributed by thermally insulated pipes to the building sub-plants where, with a heat exchanger, the water is prepared with the characteristics (pressure and temperature) of the building installation.

The advantage of large heat-producing systems is that they have much higher yields than small ones, which means a great reduction in green-house gas emissions. There is also a system of frequent maintenance and servicing and, as power plants consume a large amount of fuel, lower fuel prices can be negotiated with suppliers.

Renewable energy systems, such as geothermal energy or residual energy from thermal processes in industry or from the generation of electricity (cogeneration), should be used as heat sources. The technical disadvantages (leaks and pumping) are within an acceptable range, approximately 8 % in terms of the overall energy efficiency of the system.

The space for heat accumulation is another matter related to centralised systems to be taken into account in urban planning. In the two preceding decades, seasonal accumulation (summer–winter) has been proven to be viable. It should be noted that accumulating cooled or heated water in tanks is one of the methods widely applied to reduce peak demand. It has multiple uses: it can be used to reduce the installed power in equipment, to obtain continuous operation of the equipment without sudden fluctuations and at optimum performance levels; this means higher average efficiency and longer equipment life. In cogeneration equipment, it maximises the production of electricity; in electric refrigeration machines, electricity consumption can be increased in the off-peak rate period and reduced in the peak rate period.

The structure of a biomass system can be broken down into three distinct parts:

• fuel supply / geothermal capture system,

• power plant and

• distribution network and supply of heating to buildings.

All components of the distribution piping system must meet the technical requirements for the following standards:

• EN 253. Pre-insulated piping systems for underground hot water networks.

• EN 448. Pre-insulated fittings for underground hot water networks.

• EN 488. Pre-insulated steel valves for underground hot water networks.

•EN 489. Assembly of gaskets for pre-insulated district heating pipes.

Pipes must be of St. 37.0 BW quality steel compliant to DIN 1626 or equivalent and their dimensions must conform to ISO/DIN 2458. Foam insulation must meet the requirements of EN 253. The outer shell must meet the technical requirements of EN 253.

There is a connection box at the main entrance to each building that is being served. These connection boxes must be equipped with the necessary means for isolating circuits, automatically regulating the flow of the water supplied and controlling temperature and pressure. These dynamic regulation systems are essential so that each unit of the installation

works according to the parameters for which it has been designed and guarantees thermal comfort while curbing energy consumption.

In short, with automatic balancing, the aim is to achieve a constant flow of the hydraulic circuits that compensates for the varying differential pressures and fluctuations in those pressures at all times during the operation of the installation, thus avoiding circuits with excess or deficiency of flow that would have a negative impact on the comfort of buildings and on the pumping pressure in the production centre.

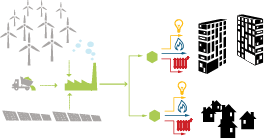

The municipality of Lugo has already completed the implementation of a thermal energy distribution network in municipal buildings on the grounds that FRIGSA used to occupy. This is a centralised thermal energy production facility running on biomass; energy is distributed by means of a district heating network to the buildings owned by the municipality in the Parque da Milagrosa in Lugo to supply heating systems, production of sanitary hot water (AQS) and air conditioning.

Thermal energy distribution network in municipal buildings on the former FRIGSA site. Source: http://lugo.gal/es

building SCALE INTERVENTION

ISSUES AFFECTED

SUITABLE FOR COMBINING WITH OTHER SOLUTIONS

MEASURING ELEMENTS

Indicator

Energy self-sufficiency

Unit

AUe (%)

Minimum goal

50%

Desirable goal

90%

Measure method / Formula

Energy self-sufficiency (%) =A / B

A: Production of renewable energies

B: Energy consumption

planning level

Master Plan

Development Plan

Building construction project

Urban planning

AGENTS INVOLVED

Planning Design team

Council arquitect

Real estate developers

Possible actions promoted by the administration

• Financial bonuses to favour their implementation

• Amendment of regulations to authorise these systems

What should we consider for its implementation?

• Pressure losses if ductwork is not properly isolated

• Planned maintenance management

• Perfectible design: planning in such a way as to enable subsequent network improvements such as system support through new renewable energy generation systems such as photovoltaics.